- Home

- About Us

- Products

- MULTI CI 500

- MULTI CI 1000

- MULTI CI 1400

- MULTI CI 2300

- Fly Ash Brick Making Machines

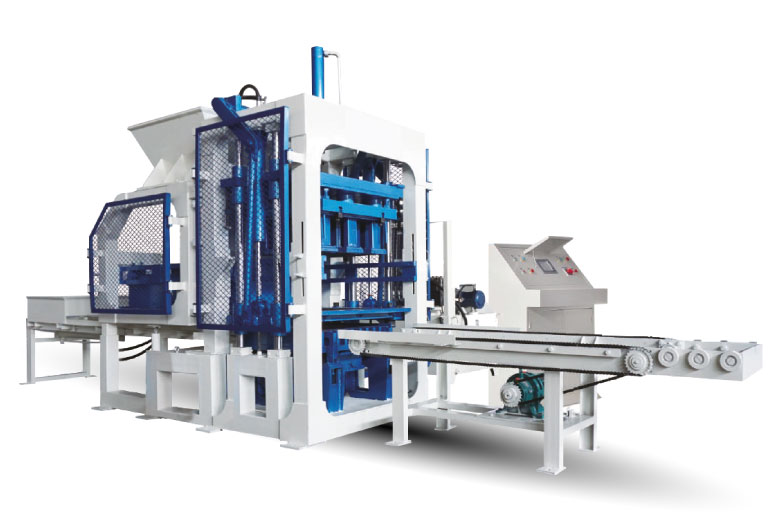

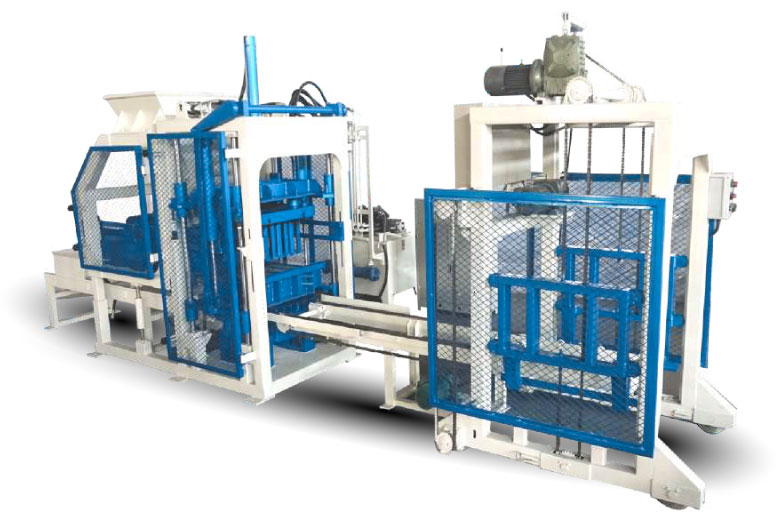

- Concrete Brick & Block Making Machines

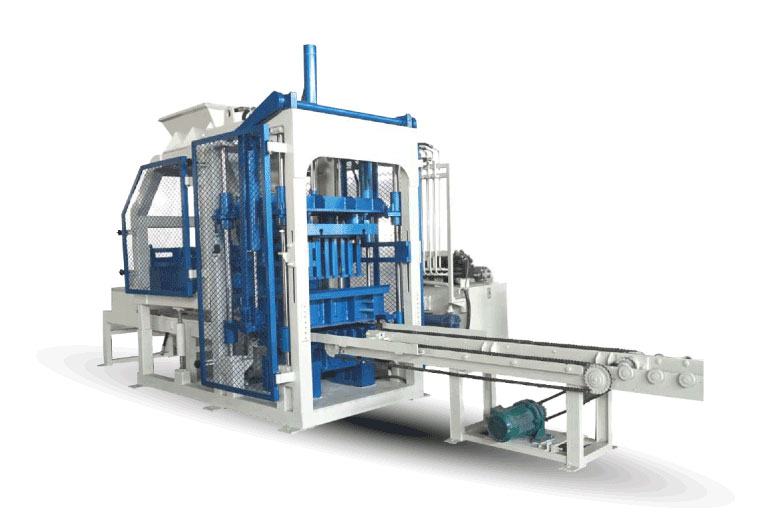

- Hollow Block and Brick Making Machine

- Solid Block Making Machines

- Interlocking Paver Block Machines

- Block Packing System

- Moveable Block Stacker

- Fork – Type Pallet Load Feeder

- Concrete Pan Mixer

- Concrete Batching Machine

- Concrete Twin Shaft Mixer

- Block & Brick Moulds

- Remote Monitoring Control System

- Videos

- Services

- BLOG

- Contact

Download Our Catalogue

Download Our Catalogue

"*" indicates required fields